Fastable CoWork™

Experience smooth and efficient operations with intelligent quality control.

The Fastable CoWork™ software suite simplifies the setup of visual and control elements on the production line, providing a more intuitive interface for inspection operations. Enhanced analysis capabilities allow quality control personnel to focus on quality assurance.

Fastable CoWork™

Experience smooth and efficient operations with intelligent quality control.

The Fastable CoWork™ software suite simplifies the setup of visual and control elements on the production line, providing a more intuitive interface for inspection operations. Enhanced analysis capabilities allow quality control personnel to focus on quality assurance.

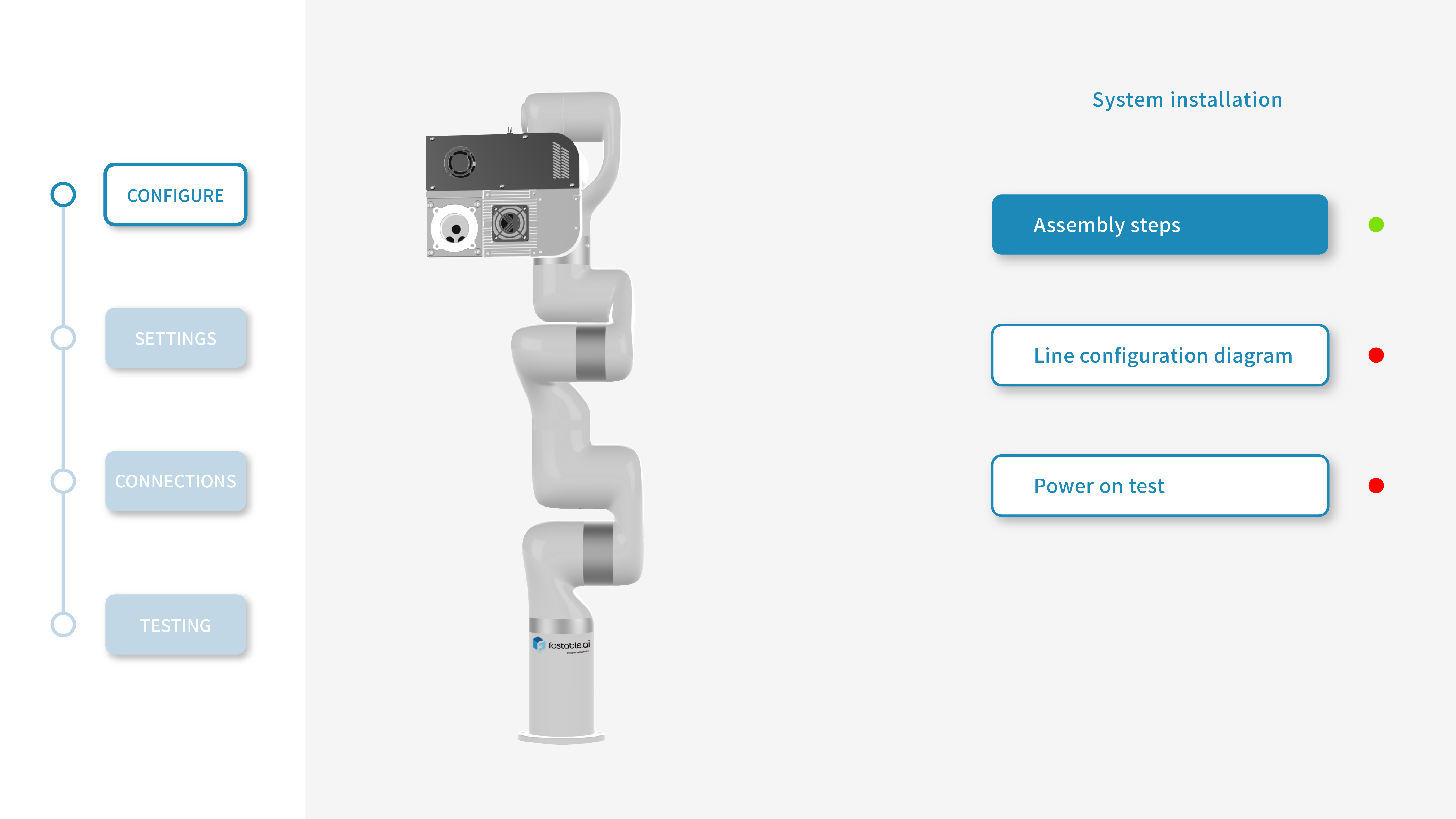

Quality Integration Suite

CoWork™ QIK (Quality Integration Kit) provides maximum flexibility and the most intuitive equipment management tools. Operations such as equipment installation, system configuration, and component maintenance can be easily completed through tablet operation. It thoroughly addresses the complexity of traditional inspection equipment and the separate maintenance of various components.

Quality Management System

Operational efficiency is crucial for a Quality Management System (QMS), as 90% of the product life cycle involves production and inspection phases. With the intuitive and interactive interface of CoWork™ QMS (Quality Management System), whether you are on the production line or managing the facility, monitoring, recording, and responding become smoother and more convenient.

Quality Management System

Operational efficiency is crucial for a Quality Management System (QMS), as 90% of the product life cycle involves production and inspection phases. With the intuitive and interactive interface of CoWork™ QMS (Quality Management System), whether you are on the production line or managing the facility, monitoring, recording, and responding become smoother and more convenient.

Quality Analysis Platform

Accurate detection records are just the first step. CoWork™ QAP (Quality Analytics Platform) offers various exploratory analysis methods, allowing you to make logical sense of the diverse data in quality control analysis. Whether it’s process improvement, preventive maintenance, or shipment grading, decisions can be made based on data-driven analytical results.