AI Creates a New Era, Achieving a Better Future.

fastable.ai

Kapito is the first Taiwanese AI startup selected subsidy for (TMG).

OUR VISION

ABOUT KAPITO

fastable = fast + stable

Fast and stable AI visual quality inspection solution.

Our founding team possesses over 20 years of experience in the field of image recognition, making us unparalleled in knowledge and proficiency.fastable.ai stands out for its ability to address labor shortages, increase customer satisfaction, prevent defects, accelerate research and development, and improve maintenance efficiency. We are committed to ensuring that your products exhibit impeccable visual quality.

fastable.ai is applicable to a range of manufacturing industries, employing roll-to-roll processes and metalworking techniques. This includes sectors such as:

1.Textiles

2.Aluminum Foil

3.Copper Foil

4.FCCL (Flexible Copper-Clad Laminate)

5.Ceramic Films (MLCC)

6.Metal Injection Molding

7.Plastic Injection Molding

fastable.ai can help you achieve intelligent and automated production processes, saving time, reducing costs, and ensuring outstanding product quality. It positions you as unbeatable in the market competition.

Dual Assurance of Efficiency and Quality

Labor Force Replenishment

Quality Satisfaction

Defects Prevention

R&D Acceleration

Precise Maintenance

FASTABLE MACHINE™

FT-R2R covering the intelligent inspection and control functions required in the roll-to-roll manufacturing process, such as entry and exit speeds, dynamic tension, edge detection, etc.

Applications: Textiles, copper-aluminum foil, coating, and more.

FT-FLOW applicable to all flow line production, with the intelligent positioning function, enabling existing production lines to achieve 100% smart inspection.

Applications: Agricultural products, food packaging, electronic assembly, and more.

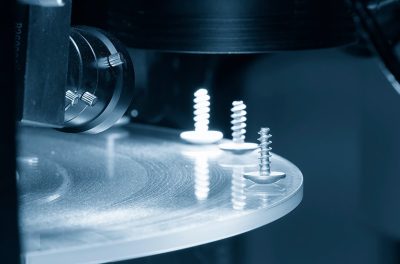

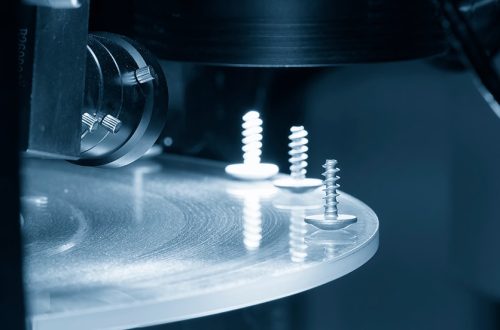

FT-FLEX designed specifically for small-batch and varied-product production lines, it offers a flexible, intuitive, and easy-to-use inspection station configuration.

Applications: Metal processing parts, mobile phone modules, battery modules, and more.

FT-RT designed for multi-sided inspection needs. Provides solutions for the integration and upgrade of existing six-face inspection machines with AI and comprehensive inspection capabilities.

Applications: Passive components, metal processing parts, and more.

FT-R2R covering the intelligent inspection and control functions required in the roll-to-roll manufacturing process, such as entry and exit speeds, dynamic tension, edge detection, etc.

Applications: Textiles, copper-aluminum foil, coating, and more.

FT-FLOW applicable to all flow line production, with the intelligent positioning function, enabling existing production lines to achieve 100% smart inspection.

Applications: Agricultural products, food packaging, electronic assembly, and more.

FT-FLEX designed specifically for small-batch and varied-product production lines, it offers a flexible, intuitive, and easy-to-use inspection station configuration.

Applications: Metal processing parts, mobile phone modules, battery modules, and more.

FT-RT designed for multi-sided inspection needs. Provides solutions for the integration and upgrade of existing six-face inspection machines with AI and comprehensive inspection capabilities.

Applications: Passive components, metal processing parts, and more.

KAPITO Express

Awards and Exhibition Achievements